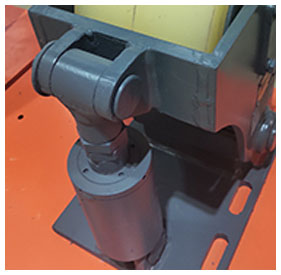

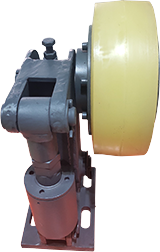

其結構由底座、擺轉臂、滾輪、緩沖器組成;滾輪罐耳結合我國礦山特點為目前運行中的提升容器更

換新型滾輪導向裝置提供了便利條件,廣泛應用與礦山,煤炭等工業生產部門。

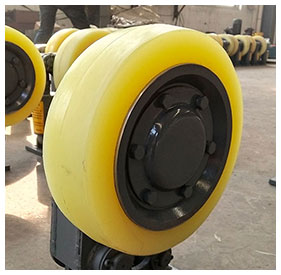

輪軸

輪軸

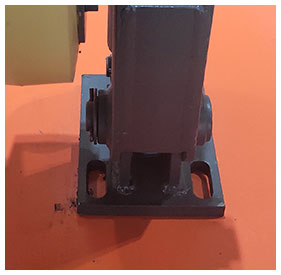

底座

底座

支架

支架

輪皮

輪皮

滾輪罐耳沿罐道運行時,因罐道的設計安裝,會產生接點、彎曲高點,輪頭會受到水平推力作用,由于支臂架、

底座和緩沖器之間的鉸接作用,使緩沖器受壓縮產生反彈力。

所以緩沖器的緩沖性能是嚴格按提升容器的重量、運行速度進行設計的,但其輪頭最大水平推力一定要小

于或等于行業標準的要求。根據以上理論設計制造出的滾輪罐耳能夠有效滿足用戶要求。

罐道輪的作用原理是滾輪受力通過支架、調節套、調節螺桿、碟簧軸施力于碟簧上,通過碟簧軸上、下運動

釋放和壓縮碟黃組實現緩沖。

承載能力大、壽命長、調整維修方便 底座等零部件采用新型材料,整體結 構強度更高抗沖擊性強。

Large bearing capacity, long service life and convenient adjustment and maintenanceThe base and other parts are made of new materials with integral structure Higher structural strength and strong impact resistance

緩沖器復位壓力小,可有效地避免滾輪與罐道產生 異常碰撞。通過杠桿傳遞 到減震筒上,同時起到導 向、緩沖與穩定作用。

The reset pressure of the buffer is small, which can effectively avoid the collision between the roller and the tank channel Abnormal collision. It is transmitted to the damping cylinder through the lever and plays a guiding role at the same time Directional, buffering and stabilizing effects.

罐道與罐耳由滑動摩擦變為滾動摩擦,因此減少 了動力消耗,降低了噪音,罐道和罐耳的磨損也 大大降低。從而,提高了罐道和罐耳的使用壽命。

The sliding friction between the tank channel and the tank ear changes to rolling friction, so it is reducedThe power consumption is reduced, the noise is reduced, and the wear of tank channel and tank ear is also reducedGreatly reduced. Thus, the service life of tank channel and tank ear is improved

滾輪端蓋中心孔上安裝有密封塞,同時端蓋上設有通氣孔,真正做到新油易入,舊油易出。

A sealing plug is installed on the central hole of the roller end cover, and an air vent is set on the end cover,原因分析:滾輪與罐道接觸過緊

排除方法:缺少潤滑脂調整滾輪接觸到罐

道即可,不要加預緊力

原因分析:擺架下鉸鏈套磨損,間隙大

排除方法:更換新套及鉸鏈

原因分析:軸承游隙太大

排除方法:拆下副輪轂,用圓螺母調整

軸承游隙

原因分析:軸承缺少潤滑脂

排除方法:注入適量潤滑脂

| 型號 | 滾輪直徑mm | 最大水平力kn | 緩沖行程mm | ||

| 單輪 |

|

L25 | 250 | 12 | 10~14 |

| L30 | 300 | 16 | |||

| L35 | 350 | 24 | |||

| L42.5 | 425 | 33 | |||

| L45 | 450 | 35 | |||

| L50 | 500 | 36 | |||

| 雙輪 |

|

LS30 | 300 | 20 | |

| LS35 | 350 | 28 | |||

| LS42.5 | 425 | 42 | |||

| LS45 | 450 | 44 | |||

| LS50 | 500 | 45 | |||